Other transition metal nitrides include zirconium nitride (ZrN), hafnium nitride (HfN) and tantalum nitride (TaN), as well as aluminum nitride (AIN), a compound of aluminum and nitrogen.

Zirconium nitride powder is yellowish brown, high hardness. ZrN coating is applied to pre-spark gap electrode of spark plug socket by vacuum plasma spraying.

Hafnium nitride powder is golden yellow, its melting point in nitride, hardness is higher, but more easy to oxidation, few applications.

Tantalum nitride is a nitride with a density and hardness。

Aluminum nitride powder is yellow, resistant to high temperature oxidation, high hardness, thermal expansion coefficient in several nitride * small, so has excellent high temperature wear resistance.

The combination of aluminum nitride with titanium carbide or titanium nitride can generate complex carbon and nitrogen compounds or compound nitride, and improve the wetting ability of Co, Ni and Fe metal melts. And it has good wear resistance at high temperature.

1) resistance

2) application

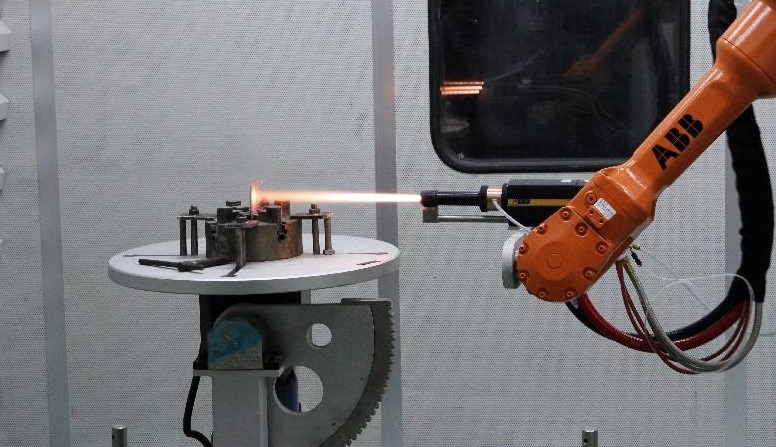

These nitride ceramic powders should be sprayed by vacuum plasma spraying process to keep the nitrogen content and phase composition of nitride coating unchanged.

Special coatings are applied according to the properties of different nitride compounds. For example, vacuum plasma spraying zirconium nitride coating on spark gap electrode of spark plug socket