Cathode material is an important part of lithium ion battery, it directly affects the battery energy density, cycle life and safety performance and other key indicators. With the continuous improvement of the mileage requirements of new energy vehicles in practical applications, the power battery related materials are also developing towards providing higher energy density. Traditional lithium ion battery has been unable to meet the current demand of graphite cathode materials high energy density has become a new hot spot for enterprises. Due to its abundant reserves and ultra-high theoretical specific capacity, silicon based anode materials are gradually becoming the most preferred choice for battery enterprises and lithium battery material manufacturers to improve cathode, and it is one of the next generation cathode materials with the most potential.

The advantages of silicon carbon are obvious

The application of silicon materials in lithium ion batteries mainly involves two aspects: one is to add nano-silicon to the negative electrode materials to form the negative electrode of silicon carbon; the other is to add organic silicon compounds to the electrolyte to improve the properties of the electrolyte.

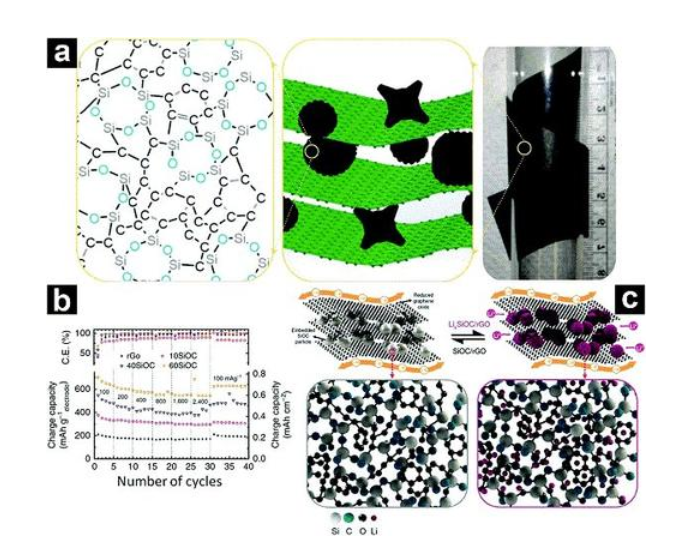

In negative electrode materials, silicon is mainly used in the form of nanometer silicon. Nanosilicon refers to crystalline silicon particles with diameter less than 5 nanometers. It is an important non-metallic amorphous material, which is often prepared by sol-gel method and other methods. Nano silicon powder has the characteristics of high purity, small particle size, uniform distribution, large specific surface area, high surface activity, low density, and non-toxic, tasteless. As the cathode material of li-ion battery, the silicon-carbon composite material composed of nano-silicon and graphite can greatly improve the capacity of li-ion battery.

At present, most lithium batteries in the market are made of graphite cathode materials. From the perspective of gram capacity and compaction density of graphite, it is difficult to improve the energy density of anode materials. In addition, there are some problems such as easy to peel off and poor cycling performance.

Compared with graphite anode materials, silicon anode materials have obvious advantage in energy density. The theoretical energy density of graphite is 372 mAh/g, while the theoretical energy density of silicon anode is 10 times higher, up to 4200mAh/g. Silicon – carbon composite material can greatly improve the capacity of single cell, effectively alleviate the industry’s concerns about the range of electric vehicles.

Of course, silicon based materials also have obvious disadvantages, mainly in the following two aspects: 1. During charging and discharging, silicon volume expansion will be caused by 100%~300%. The huge volume effect and low conductivity will limit the commercial application of silicon negative technology. 2. Silicon is a semiconductor, and its conductivity is much worse than graphite, leading to a great degree of irreversibility in the deinlay process of lithium ion, which further reduces its first Coulomb efficiency.